Inspire the Knowledge in Sewing Adjustment Epoch-making Sewing Systems in history.Digital sewing system proposes the production process added with a computerized new value to all the people who engage in production.

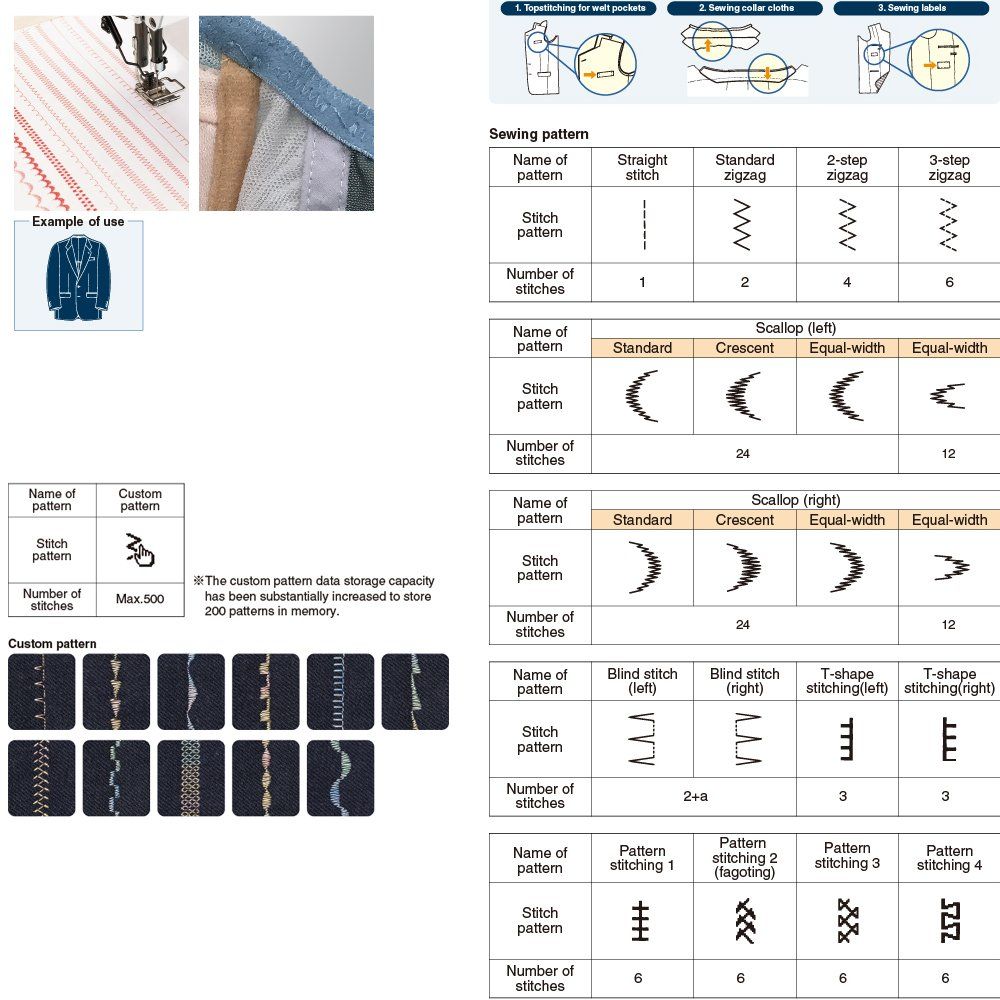

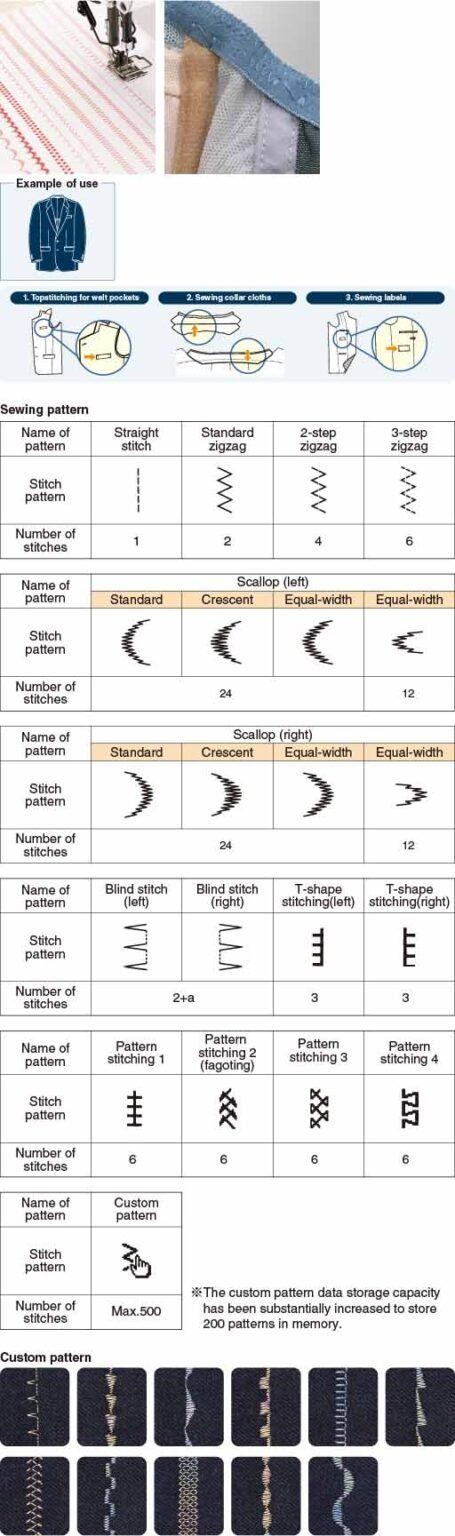

Sewing of diversified patterns is possible: The sewing machine is provided as standard with 11 types / 20 patterns of basic stitch shapes. Sewing patterns such as zigzag stitching, T stitching, and pattern sewing can be selected on the new operation panel of the main body, thereby substantially increasing the facility operation rate. In addition, a sewing pattern can be created for the brassiere sewing process for sewing a brassiere while skipping its bone portions. This also helps increase productivity. For men’s garments, the machine is used in processes such as topstitching for welt pockets, sewing collar cloths, and sewing labels. For ladies’ garments, it can perform pattern stitching for the collars and front bodies of jackets and blouses. In addition, original patterns can be created using the custom pattern feature, enabling the machine to be utilized for a broader range of uses.

Data and sewing machine management with IoT (Internet of Things) : A “Two-way” contactless communication for parameter adjustment data can be conducted with the sewing machine by a commercial Android terminal. This feature allows sewing machines in a sewing line to be uniformly set and status checked quickly, thereby contributing to the stabilization in product quality.The Control panel is standardized with USB ports, promising simplicity in data management and system updates.

Data and sewing machine management with IoT

(Internet of Things)

A “Two-way” contactless communication for parameter adjustment data can be conducted with the sewing machine by a commercial Android terminal. This feature allows sewing machines in a sewing line to be uniformly set and status checked quickly, thereby contributing to the stabilization in product quality.The Control panel is standardized with USB ports, promising simplicity in data management and system updates

Basic performance

Energy-saving function

Automatic OFF function of the operation-panel backlight

Back light of the panel is automatically turned off in the case the operation panel is not operated for a certain period of time. (The setting is from 1 to 20 minutes.)

Sleep mode (Automatic power-OFF function)

If no operation is carried out for a predetermined period of time, the power supplies to the motor, etc. (The setting is from 1 to 50 minutes.

Structure with no oil pan

The semi-dry machine head that is supplied with grease has been developed. With this machine head, oil stains on sewn products are reduced.

LED light

The LED light is provided as standard on the undersurface of arm jaw. In addition to the conventional function of the LED light, the color shade can be changed over as “white⇔neutral color (initial value)⇔incandescent” so as to help reduce the operator’s eye fatigue.

Cooling fan

The cooling fan is laid out at the position that is best to reduce the heat generated by the hook unit.

Triple hand switch

The triple type hand switch has been introduced. The switch supports many different functions such as touch-back function, mirror function and multi-layered portion correction function.

Back lever

The back lever (reverse-feed lever) is provided as standard so as to support delicate sewing operations.

Hook timing adjustment mode

Hook timing can be safely adjusted while leaving the sewing machine ON by setting operation mode to the “Hook timing adjustment mode” on the operation panel.