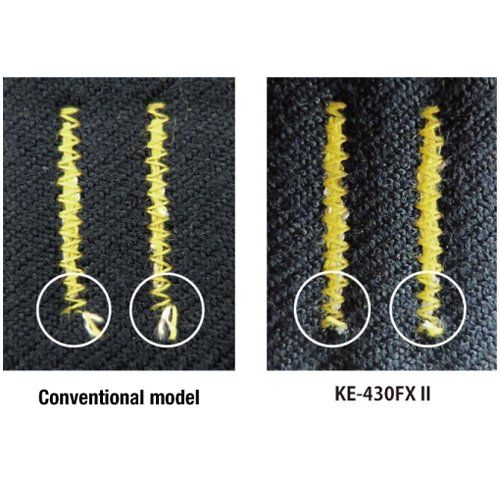

- Reduction of Disposition of Thread Ends and Enhanced Sewing Capability can Improve the Quality

- Overwhelmingly superior productivity with the world’s top-class cycle time

- Digital tension as standard equipment

- User-friendly Operation Panel

- Clean Sewing with Semi-dry Type

| KE-430FX II | 01 | 03 | 05 | 0K |

|---|---|---|---|---|

| Application | Light materials | Medium materials | Heavy materials | Knitted materials |

| Lubrication | Semi-dry | |||

| Max. sewing speed | 3,200sti/min | |||

| Max. sewing area | Max. 40x30mm | |||

| Stitch length | 0.05~12.7mm | |||

| Feed mechanism | Y-θintermittent feed mechanism (pulse-motor driven mechanism) | |||

| No. of stitches | Variable (Refer to “Program List” for details on the number of stitches for sewing patterns that are already present) | |||

| Max.No. of stitches | 5,000 stitches/pattern | |||

| Work clamp lifter | Pulse motor drive system | |||

| Work clamp height / Button clamp height | Max. 17mm | |||

| Rotary hook | Shuttle hook (double shuttle hook, optional) | |||

| Digital tension | Standard equipment | |||

| Thread wiper | Standard equipment | |||

| Thread trimmer | Standard equipment | |||

| Thread nipper | -01,-03,-0K: Standard equipment(-05: Option) | |||

| Data storage method | Flash memory (Any sewing pattern can be added using SD card) | |||

| External data storage method | SD card*1 | |||

| No. of cycle programs | 30 cycle (50 programs for each cycle) | |||

| No. of stored data | 89 sewing patterns are set already | |||

| (up to 512 patterns can be added. Total number of stitches of stored data which can be added is within 500,000*2) | ||||

| Motor | AC servo motor 550W (Direct Drive) | |||

| Weight | Machine head: Approx. 57kg, Operation panel: Approx. 0.4kg, Control box: Approx. 9kg | |||

| Power supply | Single-phase 100V/200V, 3 phase 220V/380V/400V 400VA (For single-phase 100V and 3-phase 380V/400V, the trans box is required | |||