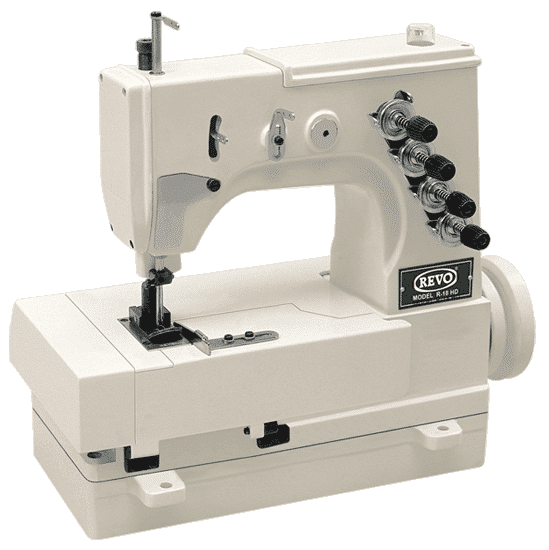

Revo® R-18 Series machines are ideal for seaming and hemming light to heavyweight material such as a jute or PP/PE woven cloth bag. These machines are designed for manufacturing HDPE/PE woven sacks and jumbo bags. The completely automatic and totally enclosed lubrication system in the R-18 machines operates using a force-fed gear pump and a pressure regulating valve. The oil lines from the pump direct the lubricant to the main moving parts and on return, the oil is efficiently recycled and pumped back into the system. Simple working of the R-18 Series allows the operator to achieve faster and better production with less downtime.

DAD shares all the following features and benefits of DA bag closing machines and more :

- Stitch length: Distance between two stitches can be varied by replacing some of the machine parts.

- No Bobbin: This feature of the R-18 Series makes it ideal for environments where quality high production is fundamental.

- Lubrication: Oil pump lubrication with oil recycling system ensures long life of machine requiring minimum maintenance.

- Reinforced mechanism: Wide presser foot resists lifting, keeping thick bags aligned for a smooth, even and better-looking stitch.

- Stitch length: The length of stitch in Revo® R-18 Series can be regulated with ease.

- Stitch width: The width of the stitch is adjustable by replacing some of the machine parts.

- Stitch variation: Single thread chain stitch is available by replacing some parts

- Tape: Any type of cotton or synthetic yarn and plastic tape can be attached and used with an optional tape attaching folder.